- One of the great challenges in launching a project like this is getting the different cultures to work together and accept each other, says Stig Munk-Nielsen, Professor, AAU Department of Energy Technology, who gathered the partners and other interested parties this week for a final symposium.

Since 2012, Stig Munk-Nielsen has been project manager for "Intelligent and Efficient Power Electronics" (IEPE) – a project with a budget of over DKK 100 million that has focused on stepping up development in power electronics. Power electronics is an umbrella term for how electrical power is controlled in electrical devices. The technology is a vital part of energy production in wind turbines and solar cells, but can be found in all power supplies.

Ready, set, collaborate

In addition to Aalborg University, the project included the Technical University of Denmark, the University of Southern Denmark and the companies KK Wind Solutions, Grundfos, CEES, Danfoss and Vestas. The project's success is owed to a well-thought-out strategy to get research and corporate cultures to work together.

- From the beginning, I was very conscious that we resist creating two silos in the project with researchers in one delivering results to the companies that would then run with them, says Stig Munk-Nielsen.

Instead he focused on blending researchers and business people, hierarchically and in terms of structure and activity.

Companies want action and immediate results, while in universities it usually takes up to a year from getting a project grant to employing the right people. I could not wait a full year to start delivering results, so I had postdocs ready from day one, he says.

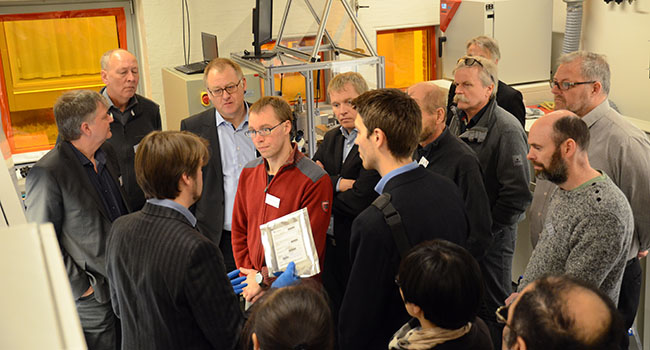

The participants in the IEPE project met at least twice each year to share their knowledge and ideas with each other.

- It has been very motivating and engaging, and this is reflected in the overwhelming level of activity in terms of both academic production and developing concrete solutions, says Stig Munk-Nielsen.

A question of trust

The cultural differences between the project partners were not only between researchers and companies but also internally between the universities.

- Usually there is some competition, not only between companies but also between the universities and the individual researchers. But in this project we managed to create a trust where the partners opened up and shared their knowledge with each other. This is significant. You can only build up that trust by creating close relationships between the partners and meeting often, says Stig Munk-Nielsen.

Seen from the outside, the competitiveness between companies like Vestas and KK Wind Solutions would have been a serious impediment to knowledge sharing, but this has not been the case in IEPE.

Productive partnership

At the IEPE final symposium Stig Munk-Nielsen thus look back on a project with many results. Over the course of five years, the ten PhD students and researchers affiliated with the project produced 136 academic publications.

At the same time, IEPE has been instrumental in developing a large amount of concrete technology demonstrators, including for the wind and solar industry. A PhD student from the Technical University of Denmark who was associated with IEPE has used the project as a springboard to establish the company Nordic Power Converters, with 10 employees, that produces power supplies.

For the final symposium, the Department of Energy Technology’s cafeteria was transformed into a regular exhibition hall in order to show the many new technology demonstrators and products that came of out the project.

- We had seven stands for the hardware that has been built. I have never heard of result like this from this type of research project. And it is due to our having had equal focus on producing research articles as well as hardware that companies can use.

FACTS

- The solutions developed in the IEPE project can be used for things like higher efficiency in wind turbines, monitoring of transistors, smaller and more efficient power supplies and testing electrical components.

- The IEPE project was funded by Innovation Fund Denmark.

- Learn more on the IEPE project website.